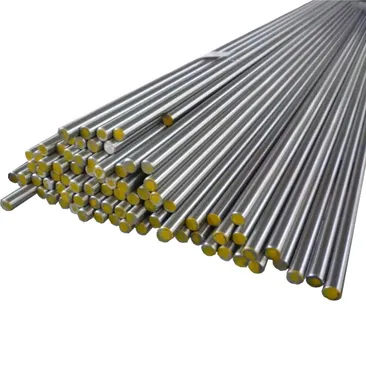

Galvanized Round Steel G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2. It has strong corrosion resistance and is mainly used for building structures with high strength requirements, such as Z-shaped steel, C-shaped steel, floor bearing plate, etc.

Galvanized round steel is a geometric object made of iron or materials with certain strength and toughness by rolling, extruding, casting, hot galvanizing anti-corrosion profile surface and other processes. Hot dip galvanized round steel is produced by advanced galvanizing process, and its surface is glossy and durable. Galvanized round steel products have been used in many fields. The advantage of hot-dip galvanized round steel is that it has a long anti-corrosion life and has been a popular anti-corrosion treatment method to adapt to a wide range of environments. It is widely used in electric power tower, communication tower, railway, highway protection, street light pole, marine components, building steel structure components, substation ancillary facilities, light industry, etc.

|

Product name

|

G550 Galvanized Round Steel

|

|

Diameter

|

16-250mm or Customized

|

|

Length

|

Customized

|

|

Advantages

|

Dia< 10.00 mm, cold drawn, on request also ground; ISO h8 Dia > 10.00 mm, cold drawn, on request also ground; ISO h9

Tighter tolerances on request

Out of roundness standard: ½ of diameter tolerance

|

|

Finish Line

|

Straightening machines

Milling and chamfering devices

Surface control (Circograph, Circoflux)

Ultrasonic control device

Antimixing control - spectrotest devices

Packaging, marking

|

|

Standard

|

AiSi, ASTM, BS, GB, JIS, EN,AS ETC.

|

|

Surface Treatment

|

Galvanized

|

|

Mechanical Property

|

Delivery status: Tensile strength (Rm): 570 -820 MPa, size depending

|

|

Bar Processing

|

Heat treatment: soft annealing, normalising, isothermal, spheroidising and stress relieving treatments, quenching and tempering

Peeling

|

|

Application

|

* Automatic lathe processing, metal stamping parts processing;

* Electronic industry, optical fiber connector, optical disc drive, scanner, medical equipment;

* Household appliances, instrumentation industry;

* Office equipment (computers, photocopiers, cameras, fax machines, etc.);

* Watch components, glasses;

* Electronic terminal pin, timer, carburetor;

* Decorations, light ornaments, cars, motorcycles, chains;

* Clean car sweepers and toys;

* Pens, handbag accessories, belt buckles, fishing gear, etc .;

* Studs, screws, nuts, pipe joints, spring seats, etc.

|

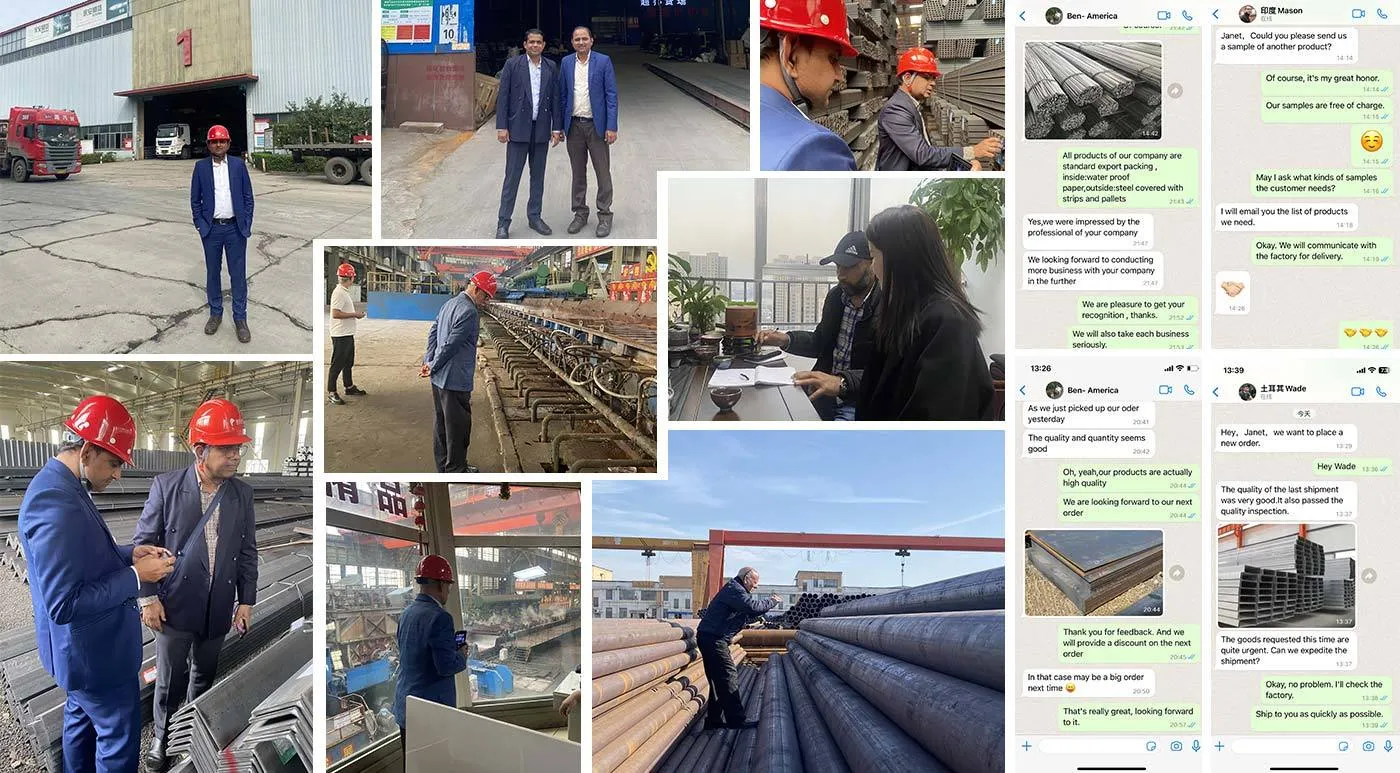

Customer group photo

Production process

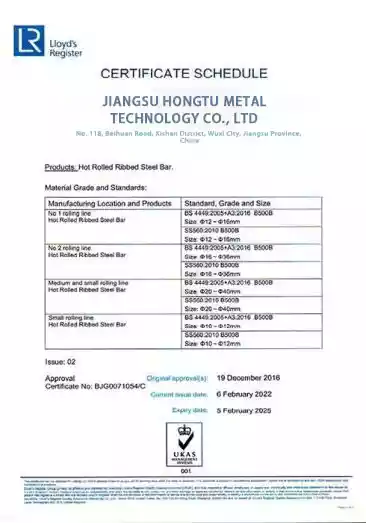

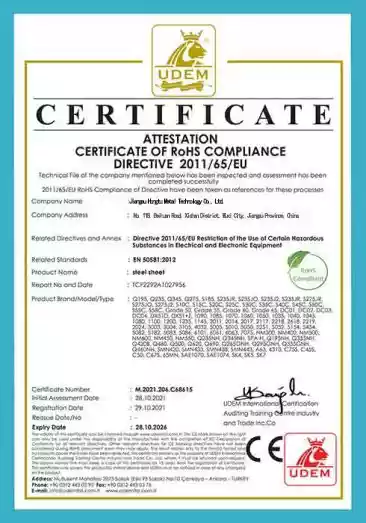

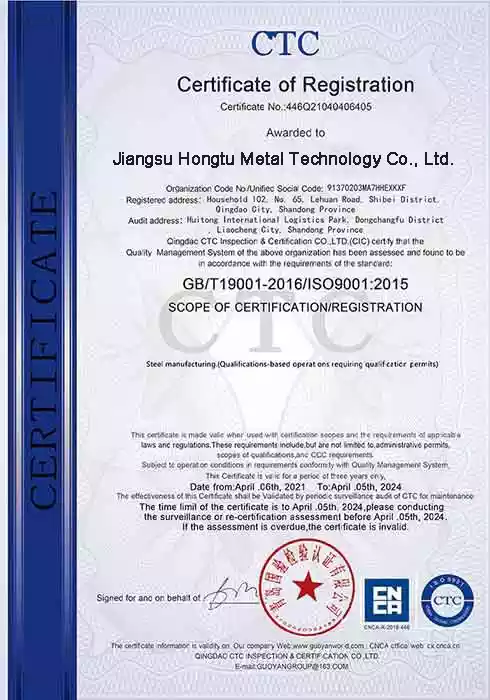

Qualification certificate