The 630 stainless steel coil finds application in a multitude of industries owing to its exceptional strength, corrosion resistance, and machinability. Commonly utilized in the manufacturing of precision components for aerospace, automotive, and marine industries, as well as in the production of surgical instruments and shafts requiring high mechanical properties. Its ability to withstand harsh environments, including high temperatures and corrosive chemicals, makes it suitable for use in oil and gas exploration, chemical processing, and offshore structures. Additionally, its magnetic properties render it valuable for electromagnetic applications, such as in motors and transformers.

|

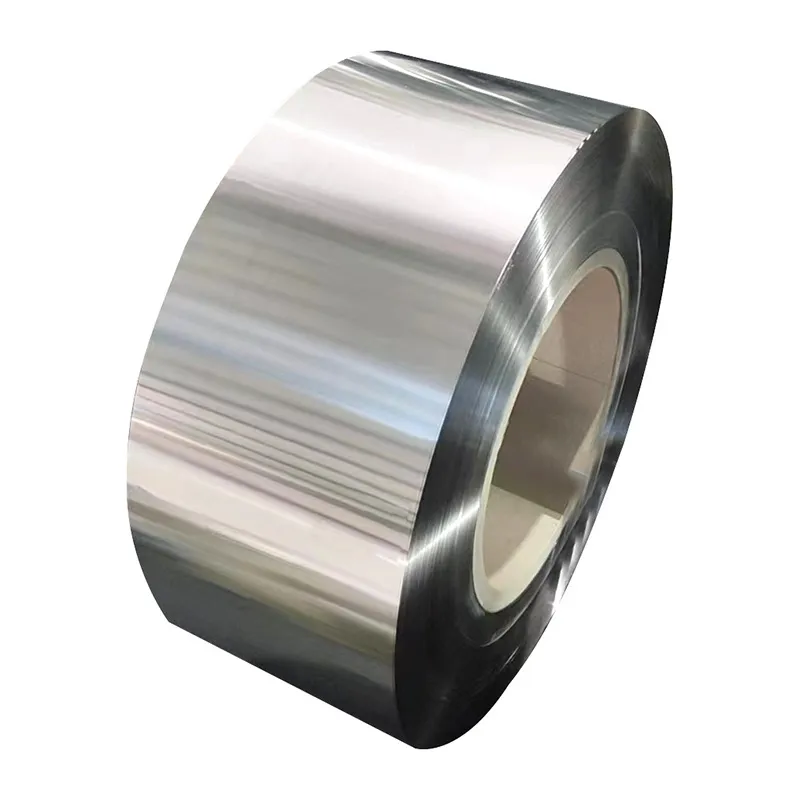

Name

|

630 Stainless Steel Coil

|

|

Standard

|

JIS, AISI, ASTM, GB, DIN, EN, BS

|

|

Material

|

630

|

|

Surface Treatment

|

BA/2B/NO.1/NO.4/4K/HL/8K/EMBOSSED or according to customer requirementg,etc.

|

|

Width

|

100mm-2500mm or as required

|

|

Thickness

|

0.1mm-12mm or as required

|

|

Length

|

As customer's request

|

|

Inspection

|

Fully accept all the third party to test before shipment.

|

|

Packing

|

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required.

|

|

Payment Terms

|

L/C, T/T ETC.

|

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

Customer group photo

Production process

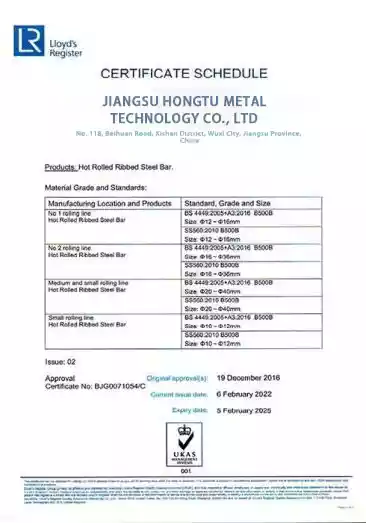

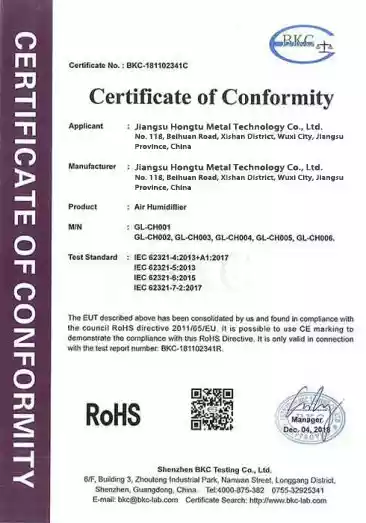

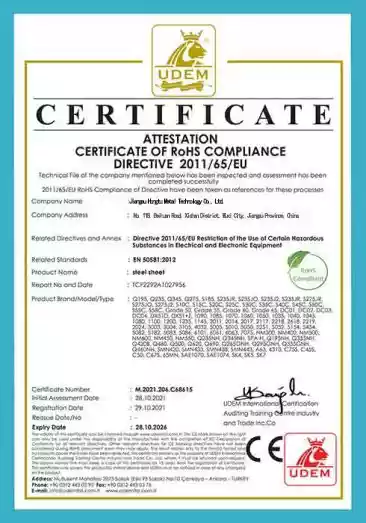

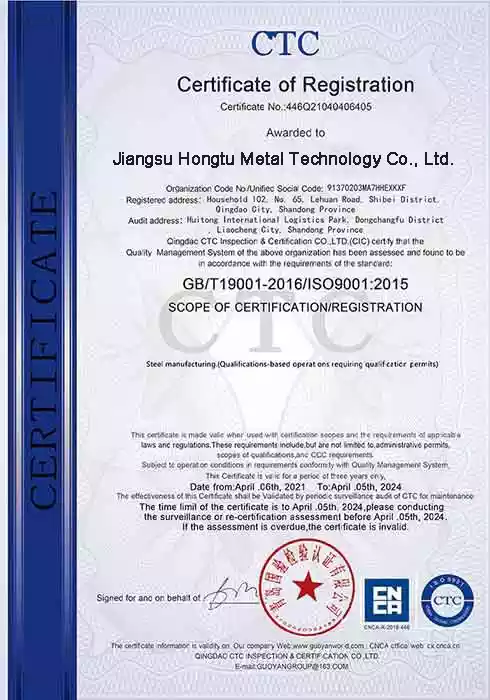

Qualification certificate