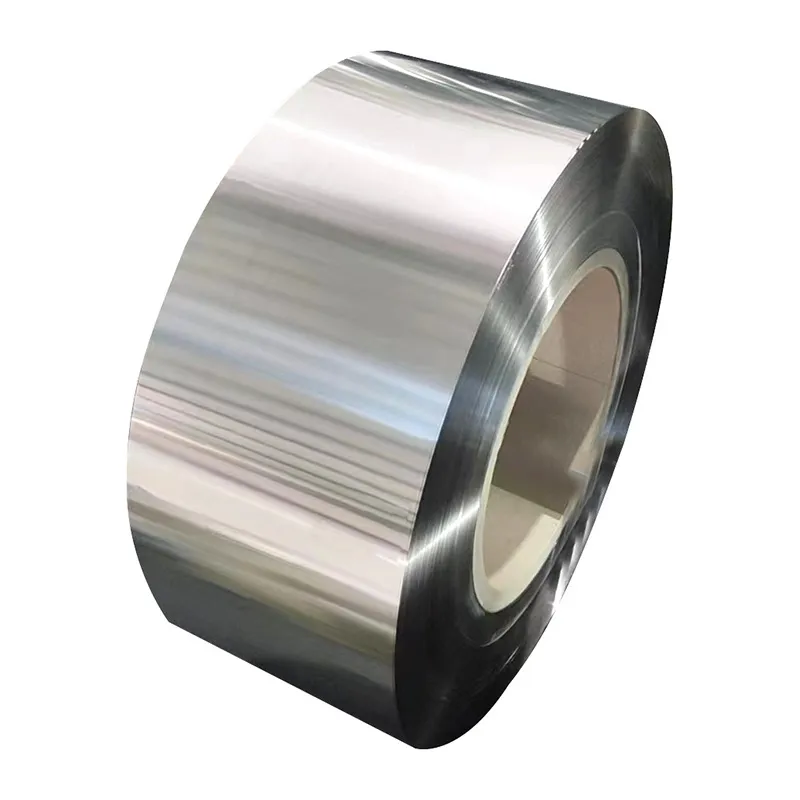

The 301 stainless steel coil serves a broad spectrum of applications owing to its excellent combination of corrosion resistance, high strength, and formability. Widely employed in industries such as automotive, aerospace, and electronics, it finds utility in manufacturing components requiring precision, durability, and resistance to harsh environments. Additionally, its suitability for fabrication processes like stamping, bending, and welding makes it a preferred choice for producing various parts, including springs, fasteners, and kitchen utensils. Its versatility and reliability make it indispensable across diverse sectors where performance and longevity are paramount.

|

Name

|

301 Stainless Steel Coil

|

|

Standard

|

JIS, AISI, ASTM, GB, DIN, EN, BS

|

|

Material

|

301

|

|

Surface Treatment

|

BA/2B/NO.1/NO.4/4K/HL/8K/EMBOSSED or according to customer requirementg,etc.

|

|

Width

|

100mm-2500mm or as required

|

|

Thickness

|

0.1mm-12mm or as required

|

|

Length

|

As customer's request

|

|

Inspection

|

Fully accept all the third party to test before shipment.

|

|

Packing

|

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required.

|

|

Payment Terms

|

L/C, T/T ETC.

|

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

Customer group photo

Production process

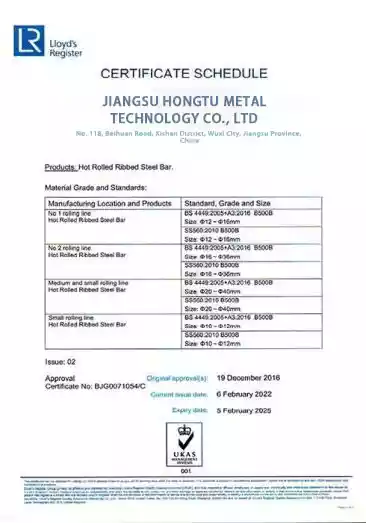

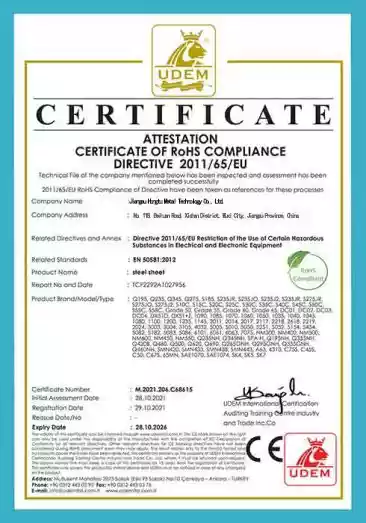

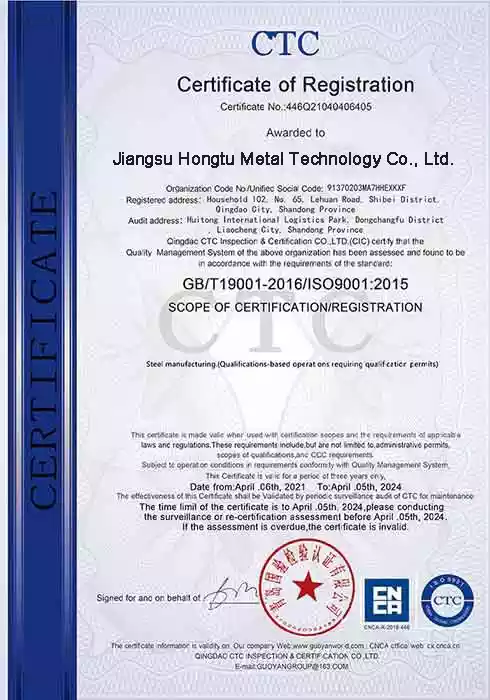

Qualification certificate