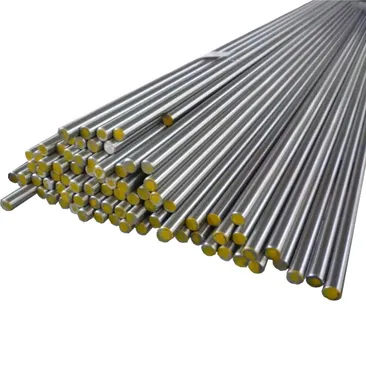

The 904 stainless steel coil serves a wide range of applications, particularly in industries requiring exceptional corrosion resistance and high strength. Commonly utilized in sectors such as oil and gas, chemical processing, and marine engineering, it excels in harsh environments where exposure to corrosive substances and extreme conditions is prevalent. Its high chromium, nickel, and molybdenum content enhance resistance to pitting, crevice corrosion, and chloride stress corrosion cracking, ensuring longevity and reliability in demanding settings. Additionally, its versatility and formability enable efficient fabrication into critical components across various sectors, making it a preferred choice for challenging operational environments. Overall, the 904 stainless steel coil stands as a dependable solution, offering exceptional performance and durability in specialized industrial applications.

|

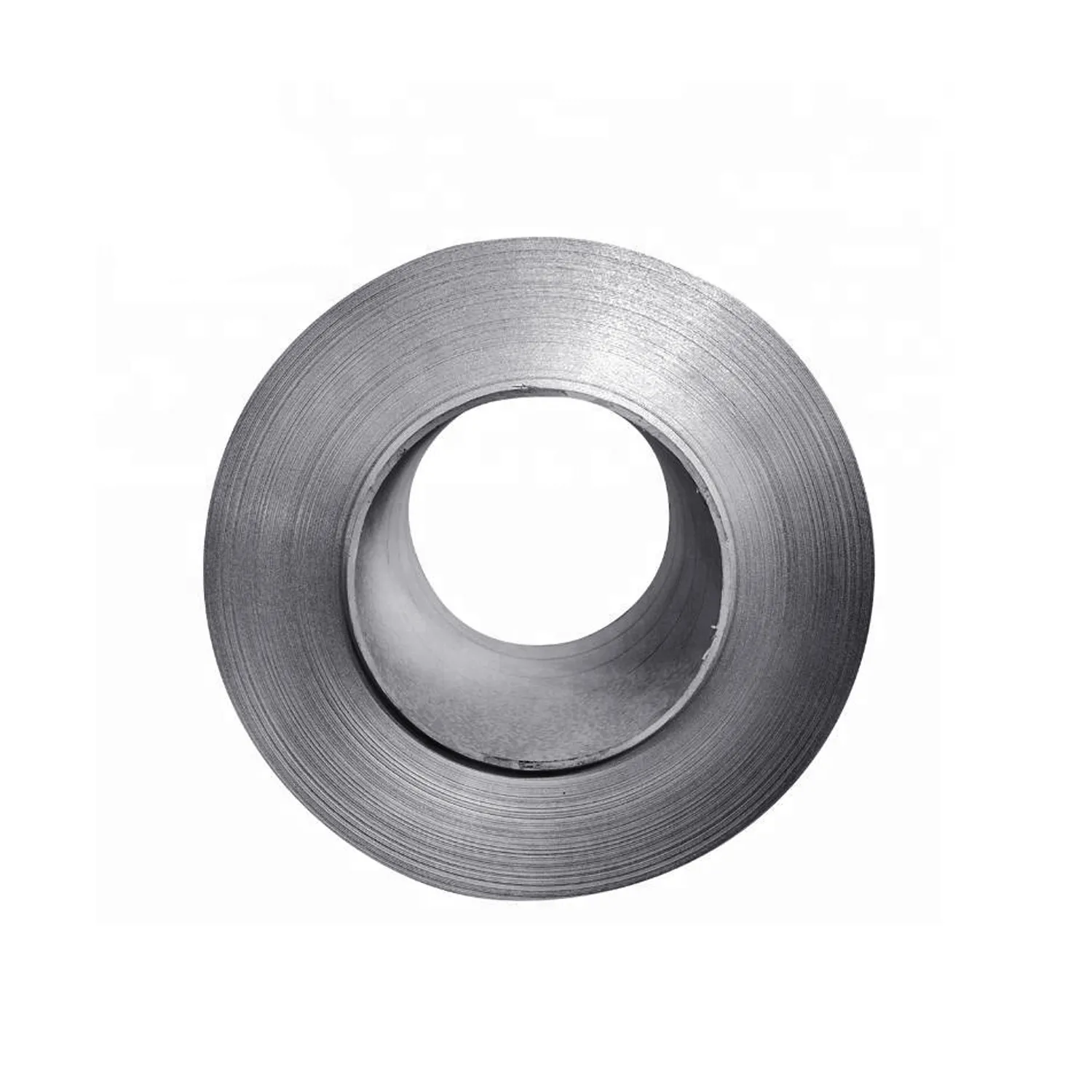

Name

|

904 Stainless Steel Coil

|

|

Standard

|

JIS, AISI, ASTM, GB, DIN, EN, BS

|

|

Material

|

904

|

|

Surface Treatment

|

BA/2B/NO.1/NO.4/4K/HL/8K/EMBOSSED or according to customer requirementg,etc.

|

|

Width

|

100mm-2500mm or as required

|

|

Thickness

|

0.1mm-12mm or as required

|

|

Length

|

As customer's request

|

|

Inspection

|

Fully accept all the third party to test before shipment.

|

|

Packing

|

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required.

|

|

Payment Terms

|

L/C, T/T ETC.

|

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

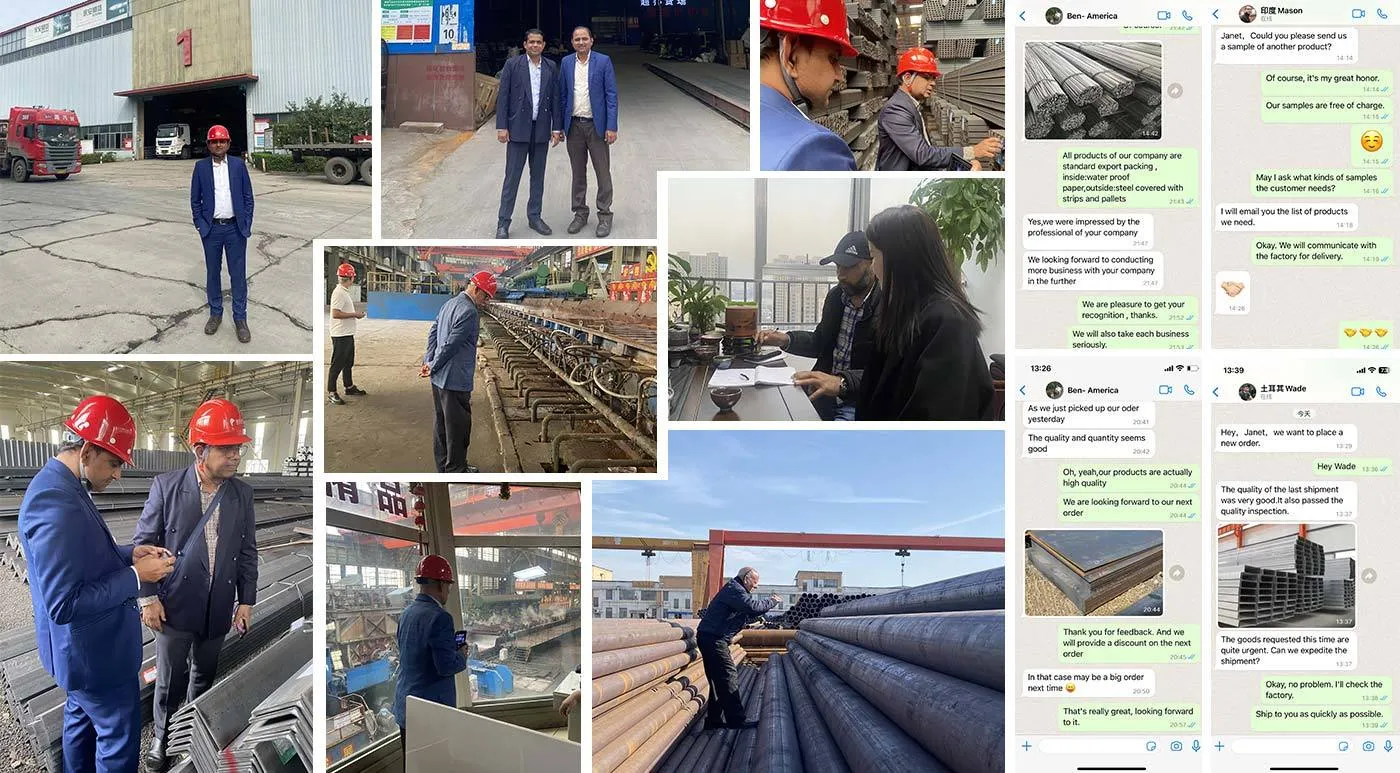

Customer group photo

Production process

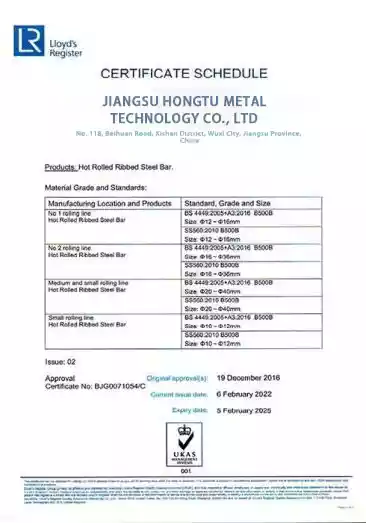

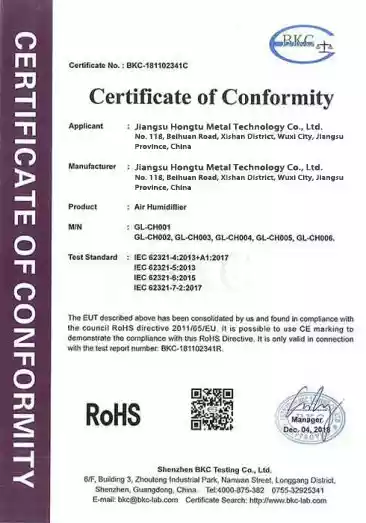

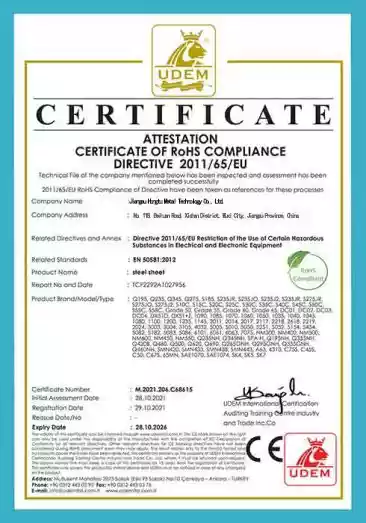

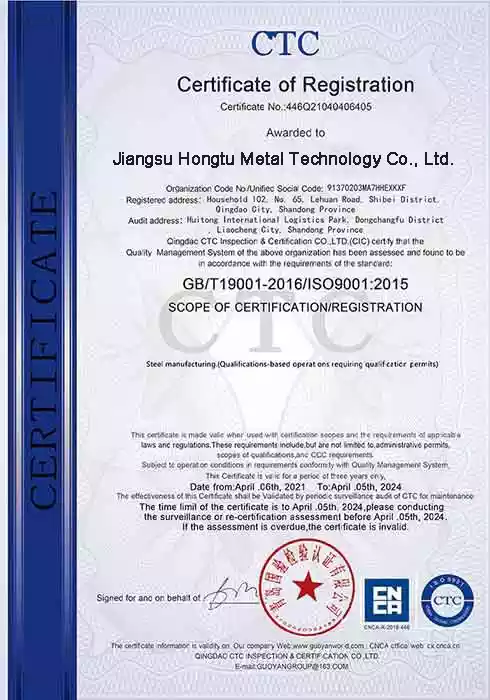

Qualification certificate