Product introduction

ERW Steel Pipe

Pipe Type: ERW Pipe, ERW Steel Pipe, Electric Resistance Welded Pipe

Application: For Low Pressure Fluid Transmission, Machinery Manufacturing

Specification: OD: 21.3mm ~ 660mm

WT: 1mm ~ 17.5mm

LENGTH: 0.5mtr ~ 22mtr (5.8/6/11.8/12 meters, SRL, DRL)

Standard & Grade: API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

ASTM A53, ASTM A500, JIS G3466, ASTM A252, ASTM A178, AN/NZS 1163, AN/NZS 1074, EN10219-1, EN10217-1

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Production Process for ERW steel pipe:

1.Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Supercoil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming --- 9. Electric induction welding --- 10. Ultrasonic detection for weld seam --- 11. Medium frequency heat treatment --- 12. Air cooling --- 13. Water cooling --- 14. Sizing --- 15. Flying cutting --- 16. Flush-out --- 17. Cropping --- 18. Flattening testing --- 19. Straightening --- 20. End facing and bevelling --- 21. Hydrodynamic testing --- 22. Ultrasonic detection for weld seam --- 23. Ultrasonic detection for pipe end --- 24. Visual and dimensions inspection --- 25.Weighting and measuring --- 26. Marking --- 27. Coating --- 28. Pipe-end protection --- 29. Bending --- 30. Shipping

Specification of ERW steel pipe:

|

API 5L/ASTM A53 GR.B (Small Diameter ERW Steel Pipe)

|

|

Outside Diameter

|

Wall Thickness

|

Outside Diameter

|

Wall Thickness

|

|

外径 (mm)

|

壁厚 (mm)

|

外径 (mm)

|

壁厚 (mm)

|

|

33.4

(1")

|

2.1-2.4

|

Φ133

|

3.0-5.75

|

|

2.5-3.25

|

6.0-7.75

|

|

3.5-4.0

|

8.0-10

|

|

42.3

(1.2")

|

2.1-2.4

|

Φ139.7

(5″)

|

3.0-4.5

|

|

2.5-3.5

|

4.75-5.75

|

|

3.75

|

6.0-7.75

|

|

4.0-5.0

|

8.0-10

|

|

48.3

(1.5")

|

2.1-2.4

|

Φ152

|

3.0-4.5

|

|

2.5-3.25

|

4.75-5.75

|

|

3.5-3.75

|

6.0-7.75

|

|

4.0-4.25

|

8.0-10.0

|

|

4.5-6.0

|

Φ159

|

3.25-6.75

|

|

Φ60.3

(2″)

|

3.0-4.0

|

6.8-7.75

|

|

4.25-4.75

|

8.0-10.0

|

|

5.0-5.75

|

10.0-11.75

|

|

Ф73

|

3.0-4.75

|

Φ165

|

3.0-6.0

|

|

4.8-5.25

|

6.25-7.0

|

|

5.5-7.0

|

/

|

|

Φ76.1

|

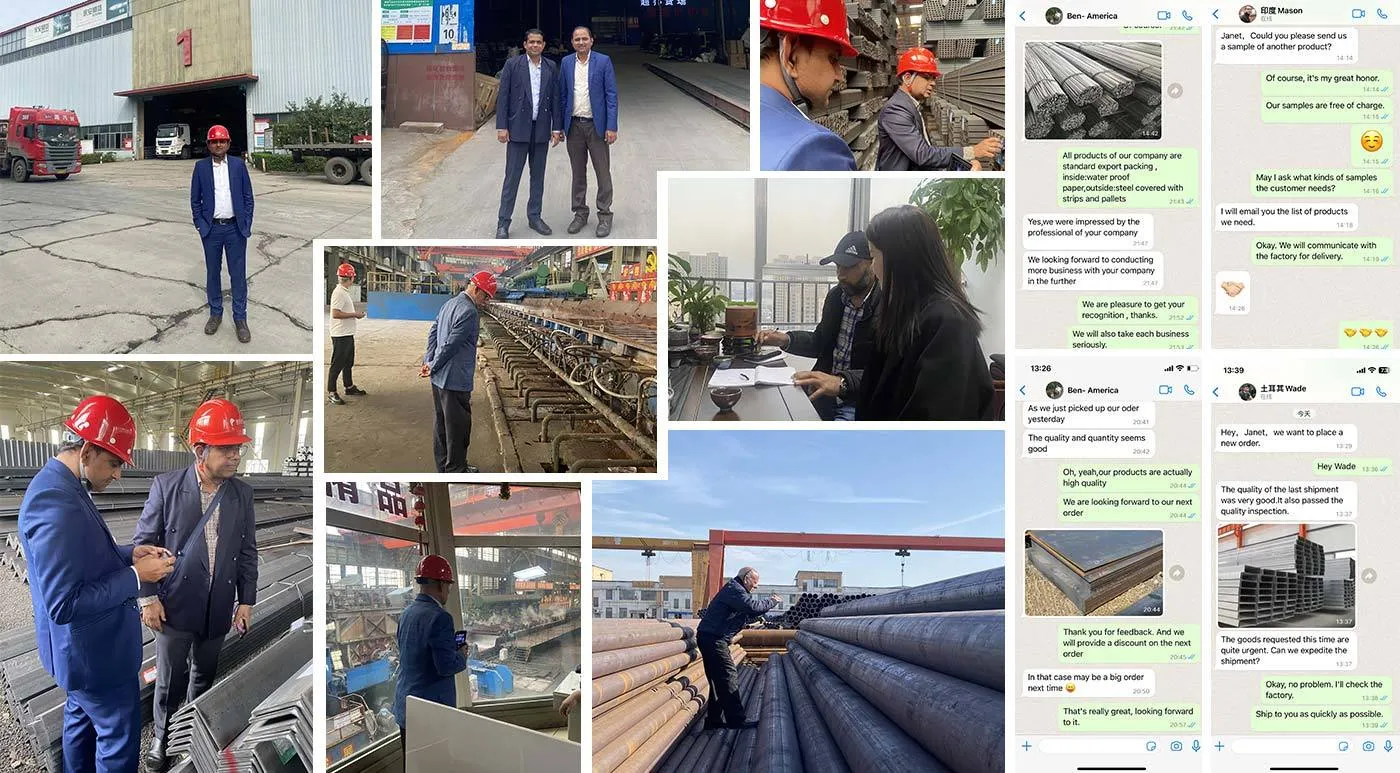

Customer group photo

Production process

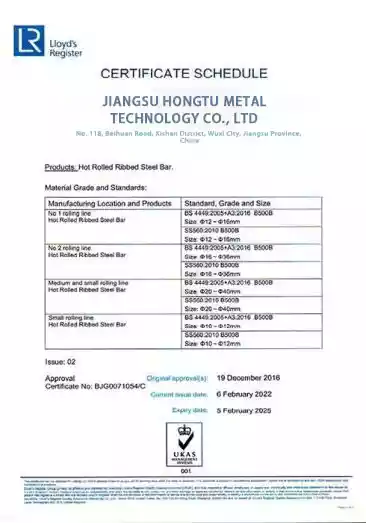

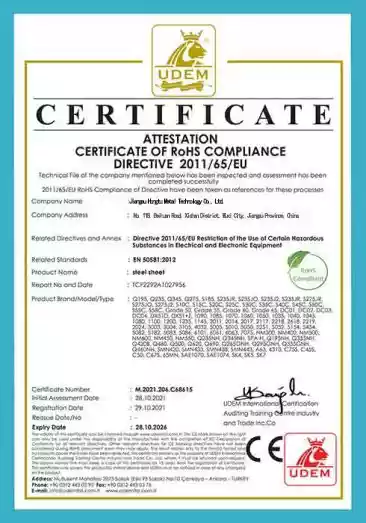

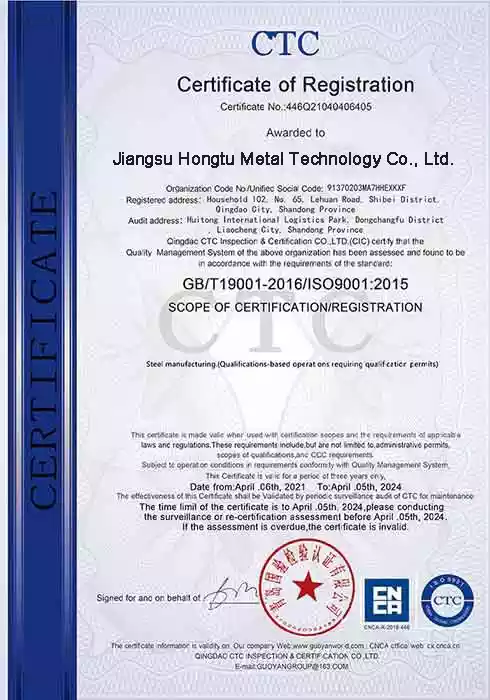

Qualification certificate